DCARB TECHNOLOGY DELIVERS

BIG FUEL AND BIG EMISSION REDUCTIONS

Our patented DCARB hydrogen technology is an aftermarket device designed

to reduce fuel consumption, emissions and engine maintenance. Hydrogen burns 10 times faster than Diesel fuel, adding a small amount to the combustion process causes fuel to burn more completely, this results in higher peak pressure closer to the Top Dead Centre (TDC). Achieving a result closer to TDC will produce a higher effective pressure in which to carry out the work cycle, significantly reducing fuel consumption and emissions.

Learn more about the industry leading DCARB Technology.

BENEFITS

75%

Particulates Emissions

$

Oil & Maintenance Cost

4-6%

Horse Power/Torque

5-15%

Fuel Consumption

THE HYDROGEN SOLUTION

The Addition of Hydrogen Cleans & Co-Fuels

RIGHT NOW

Driving with engine Optimized Gases Injection parts

We carefully monitor engine data & inject H2 & O2 into the engine air intake for varying driving conditions.

SUMMARY OF CURRENT DIESEL COMBUSTION ISSUES

Low NOX Requirements

Engines designed for lower NOX have lower in cylinder combustion temperatures which leads to:

Carbon Build Up

This is caused from from incomplete in cylinder combustion. The more complex the Hydrocarbon Chain in the fuel (Diesel is complex) the more difficult the combustion process relies on the heat to completely combust the Hydro Carbon to CO2.

Time for Combustion

Low Timing Advance (S.O.I. near T.D.C.) leaving less time for the combustion process. Diesel is a comparatively slow burning fuel, so the reduction in injection timing as resulted in lower net efficiency from the combustion process.

Advantages of Hydrogen Inclusion

- Engine Carbon Removal

The addition of free H2 atoms into the combustion process combines to help remove carbon build-up in 2 ways:

- Additional Hydrogen helps the combustion process in terms of providing more Hydrogen > Carbon thus allowing for a better, more complete combustion, thus eliminating residual carbon. This is evident in University studies regarding Particulate Matter dropping significantly with the inclusion of H2.

- The free H2 molecules can actually bond with the residual carbon within the engine frame turning the Carbon into a low-energy hydrocarbon and thus allowing it to simply ‘burn off’ back into H2O + CO2.

Improving

- Compression Sealing Ring Performance

- Nozzle Atomization of Fuel

- Air flow through Ex. Ports + Turbo

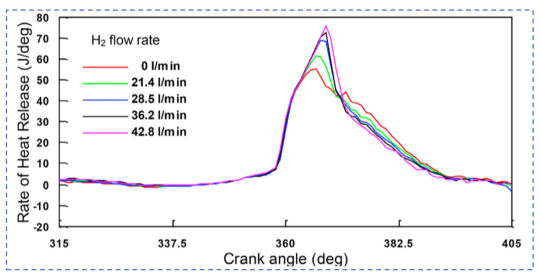

- Time for Combustion

Flame front speed for Hydrogen and Oxygen is nearly 10 times faster than normal Diesel Combustion. This means that we can minimize or reverse the negative impact of the reduced Start of Injection timing on MEP (Mean Effective Pressure) of the combustion process.

- Karago ̈z1 et. al. study

You can see from the heat release rate shown that the time to burn the fuel is significantly decreased and the phenomenon can be utilised to reverse the negative effects of NOX tuning methods.

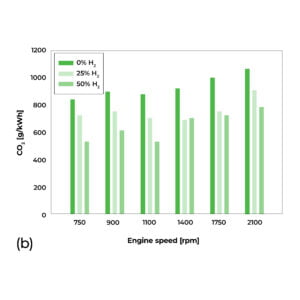

- Emissions

- Significantly Reduced Particulate Emissions

- Reduced CO and CO2 Emissions

- Reduced Exhaust Gas Temperatures